Our process

Supercharging nature’s best. With Wood technology.

Augmented Wood™.

Augmented performances.

Construct on a new level.

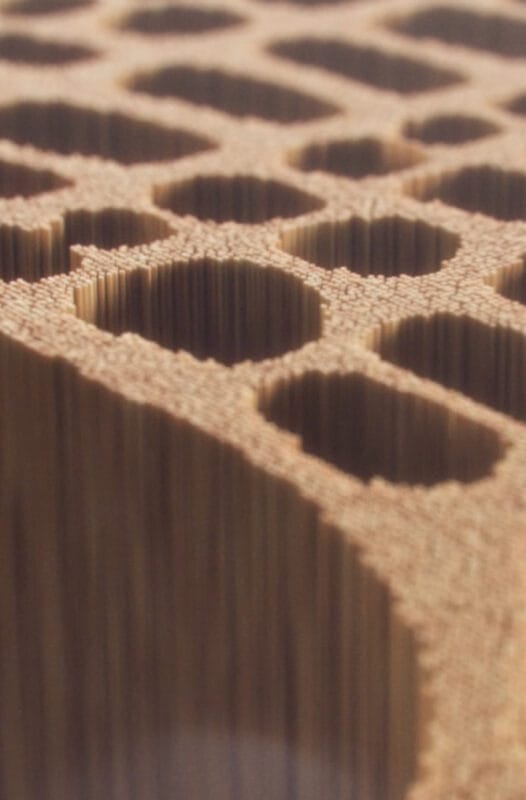

Woodoo reengineers

Wood’s microstructure

We’ve cracked the code to strengthen and enhance wood’s durability by transforming its structure through advanced wood technology. Through a process called delignification, we remove lignin—the “glue” that holds wood fibers together but also weakens it. Lignin:

- Forms weak chemical bonds with cellulose, reducing strength

- Attracts insects and termites, causing degradation

- Oxidizes with humidity and sunlight

We replace lignin with a high-performance cellular binder, creating a revolutionary composite material that redefines what wood can do for the construction application.

1. UNDERUTILIZED / LOW-GRADE WOOD

Sourced from certified regenerative forestry practices

2. CHEMICAL TREATMENT

Transforming wood’s structure at the molecular level

3. CELLULAR BINDER

Impregnating wood and unleashing its properties

Where wood technology

Meets Manufacturing Innovation

3,000 M2

factory surface area

60,000 LM

capacity per year, for cladding application

2,000 M3

capacity to come for strutural application

A pioneering

research environment

Troyes & Paris, France

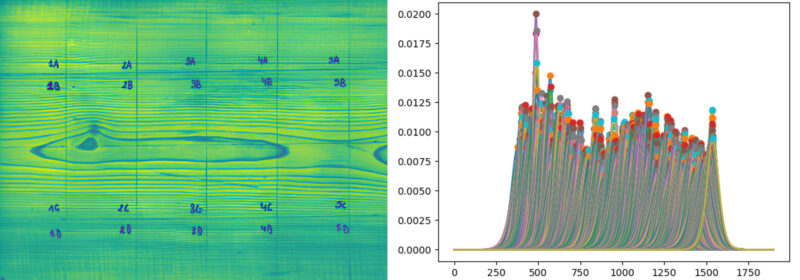

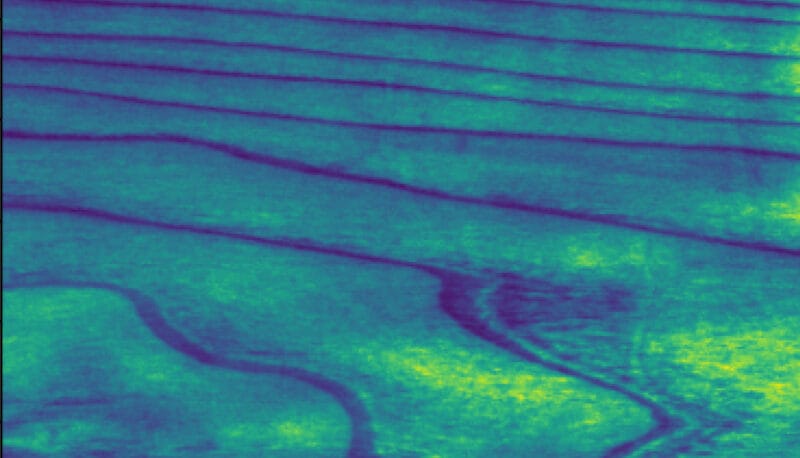

From molecular to

the cellular scale

Innovations only make an impact when they move beyond the lab.

At Woodoo, our Innovation Platform leverages the creative freedom of research to fuel a constant stream of breakthroughs in wood technology.

Our team continuously prototypes, iterates, and refines our product development roadmap to ensure excellence at every stage.

This multidisciplinary group includes chemists, composite material experts, physicists, AI and data scientists, processing engineers, structural engineers, and product managers.

By enhancing wood at the molecular level, we’ve achieved over 80 patents and earned global recognition for our pioneering work in bioengineered materials.

Leveraging ai for mATERIAL science

From a new material

to a certified product

Our manufacturing site is quickly ramping up to meet growing demand with wood technology.

STACK is first produced as standard boards, which are then assembled into larger components for facades or structural applications.

Our expertise spans across a range of wood sources, ensuring consistent product quality and reliability. We closely monitor the life cycle and environmental impact of our materials, ensuring top-tier performance.

This facility also serves as a training hub for subcontractors teaching them the specifics of our unique process.

Our experienced team includes production supervisors, LEAN manufacturing specialists, quality control inspectors, process engineers, supply chain managers and operators.

Together, they ensure excellence and efficiency at every step.

Troyes, France

Where do we stand

on production

ACHIEVED

TO IMPLEMENT

LOCAL SOURCING

of raw materials

RECYCLED RESIN

Using scrap as resources

ENERGY EFFICIENCY

Constant optimization of energy use

STRICT INDUSTRY PROCESS

NF and ISO standards

BIO-BASED RESIN

For all our production

0% WASTE TARGET

On the process